X

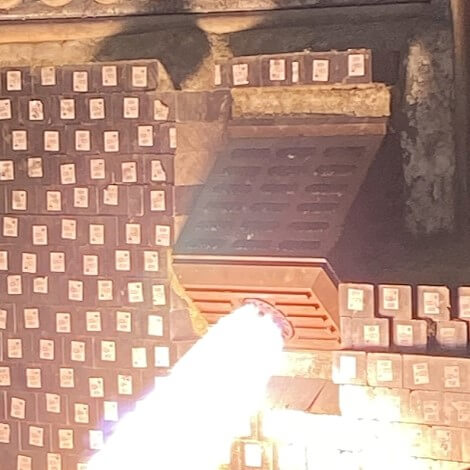

FLASH STOP

BACKFIRE PREVENTING SYSTEM

CONCEPT

The FLASH STOP system has been developed to prevent accidental damages due to oxygen and fuel backfiring in the copper front face, injector tip and water cooled panels caused by the presence of a thick piece of heavy scrap in front of the injector tip. The system is made up of temperature sensors continuously detect the variance of the copper temperature.

In case of backfiring, the temperature on the front panel will rapidly increase over the alarm threshold. Then, the automation system will automatically reduce the burner power or switch-off the injector. As soon as the temperature returns to its normal value, the system will turn on the injector again.

CLICK HERE TO DOWNLOAD FLASH STOP CATALOGUE

Higher burner efficiency

Reduced maintenance

Added safety by reducing water leakages inside the eaf

Increased life time of injector tips, copper blocks and water cooled panels