X

Chemical Energy Package

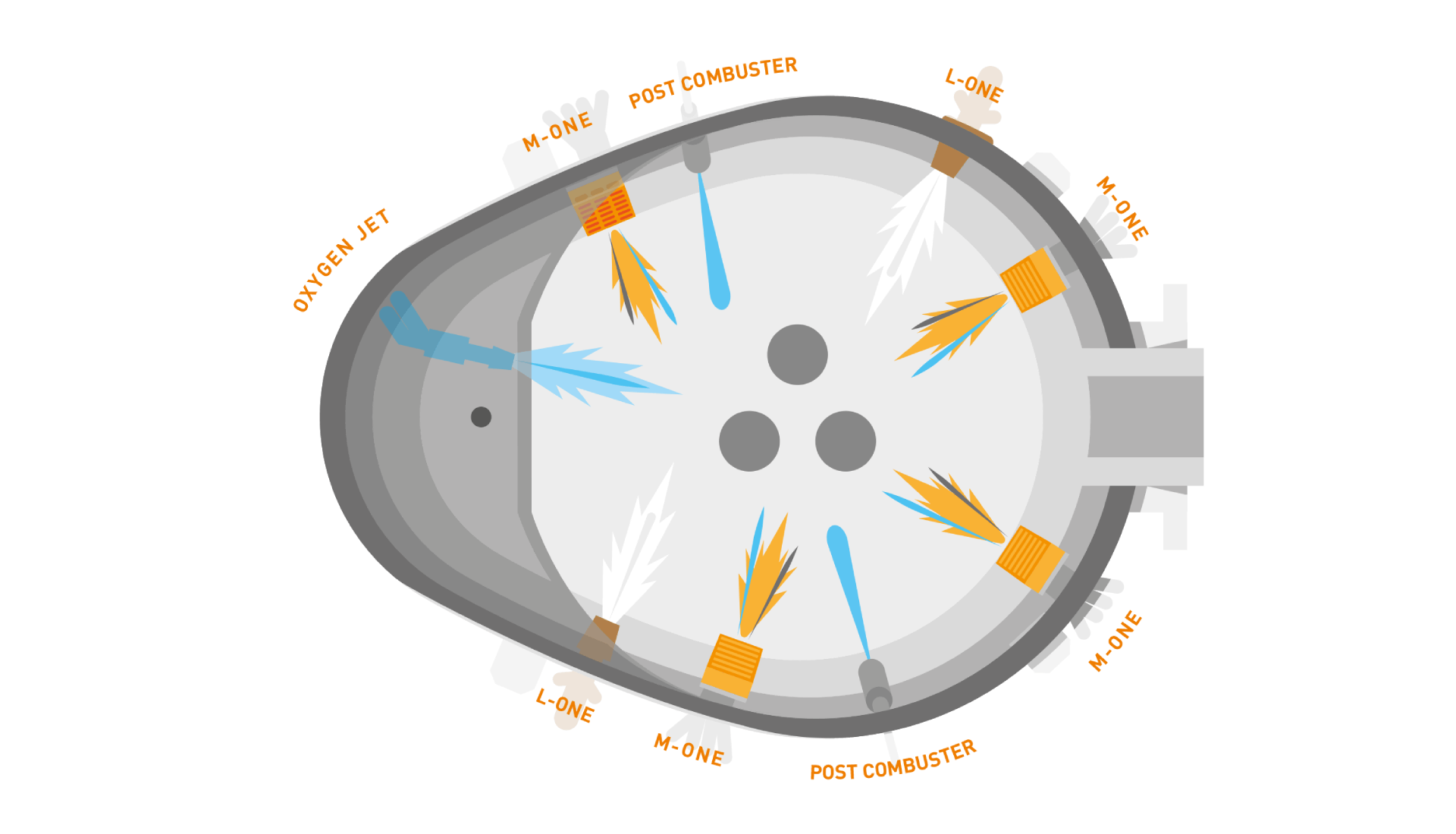

Oxygen, carbon and lime side wall injection technology for electric arc furnaces

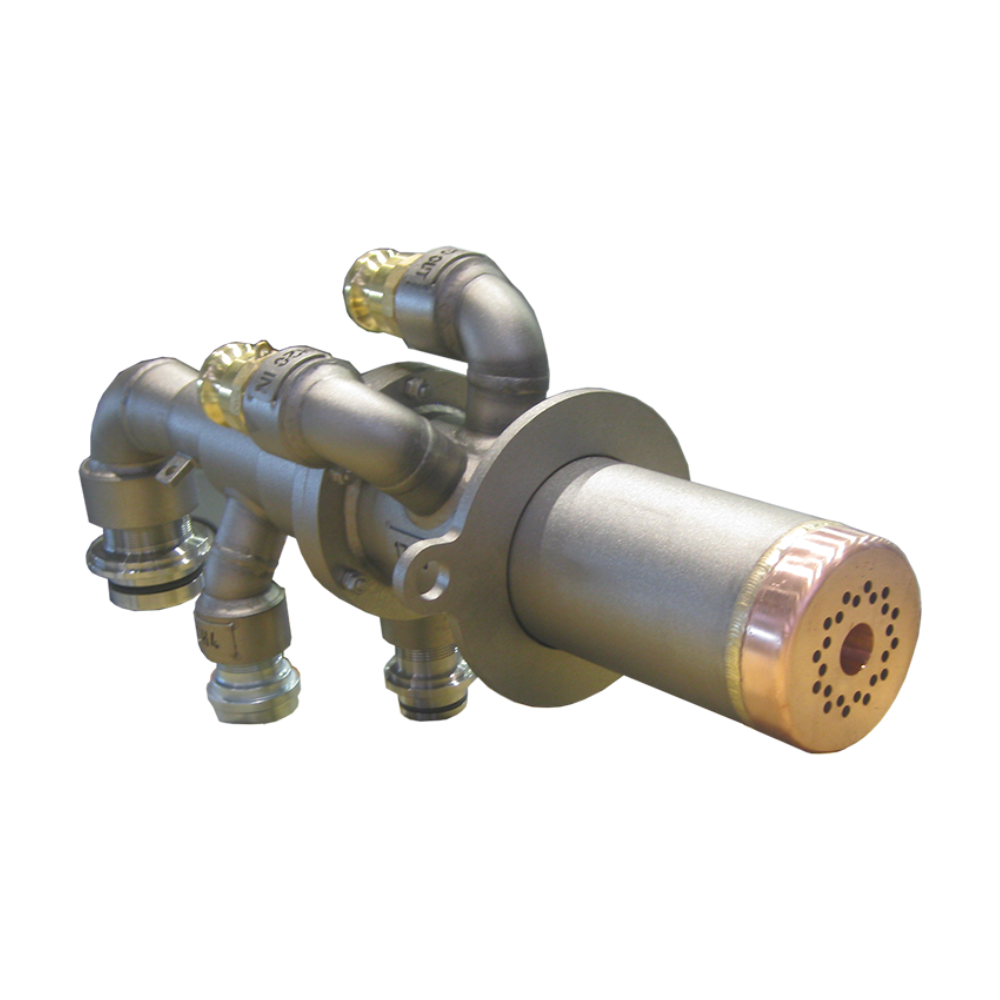

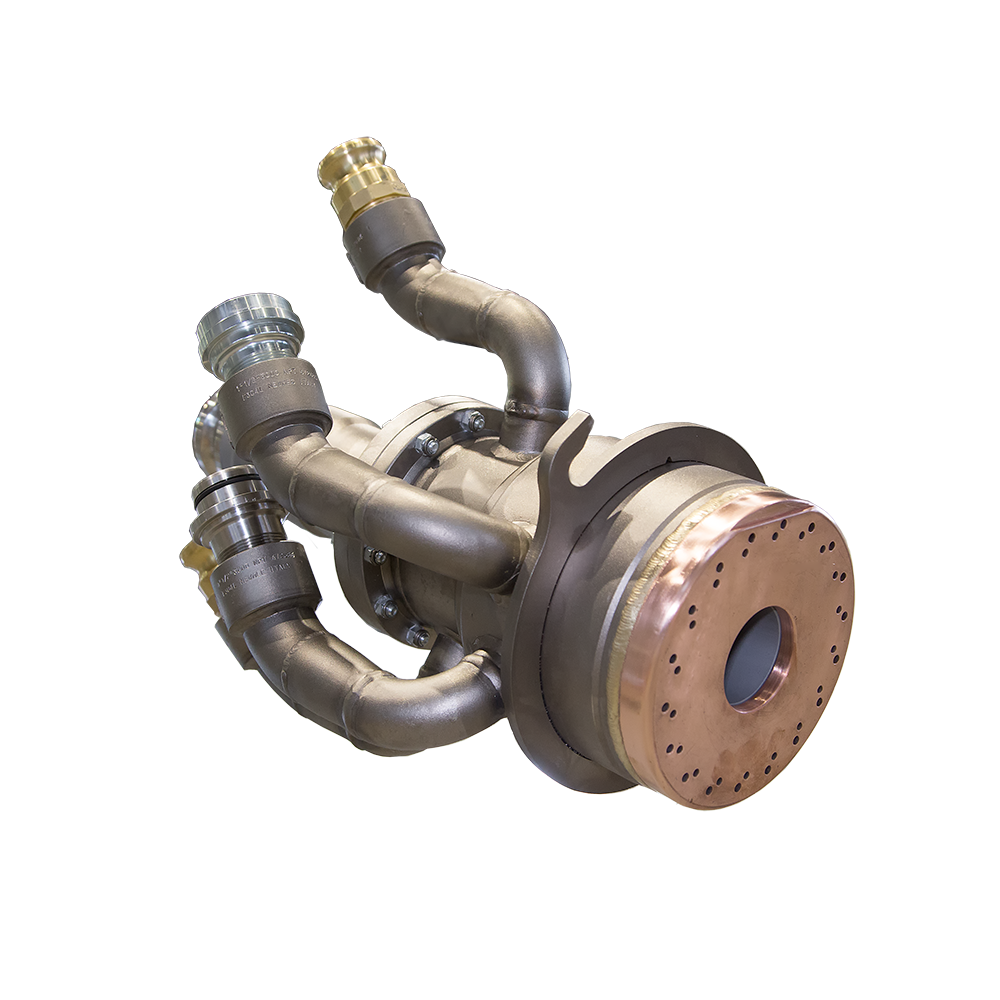

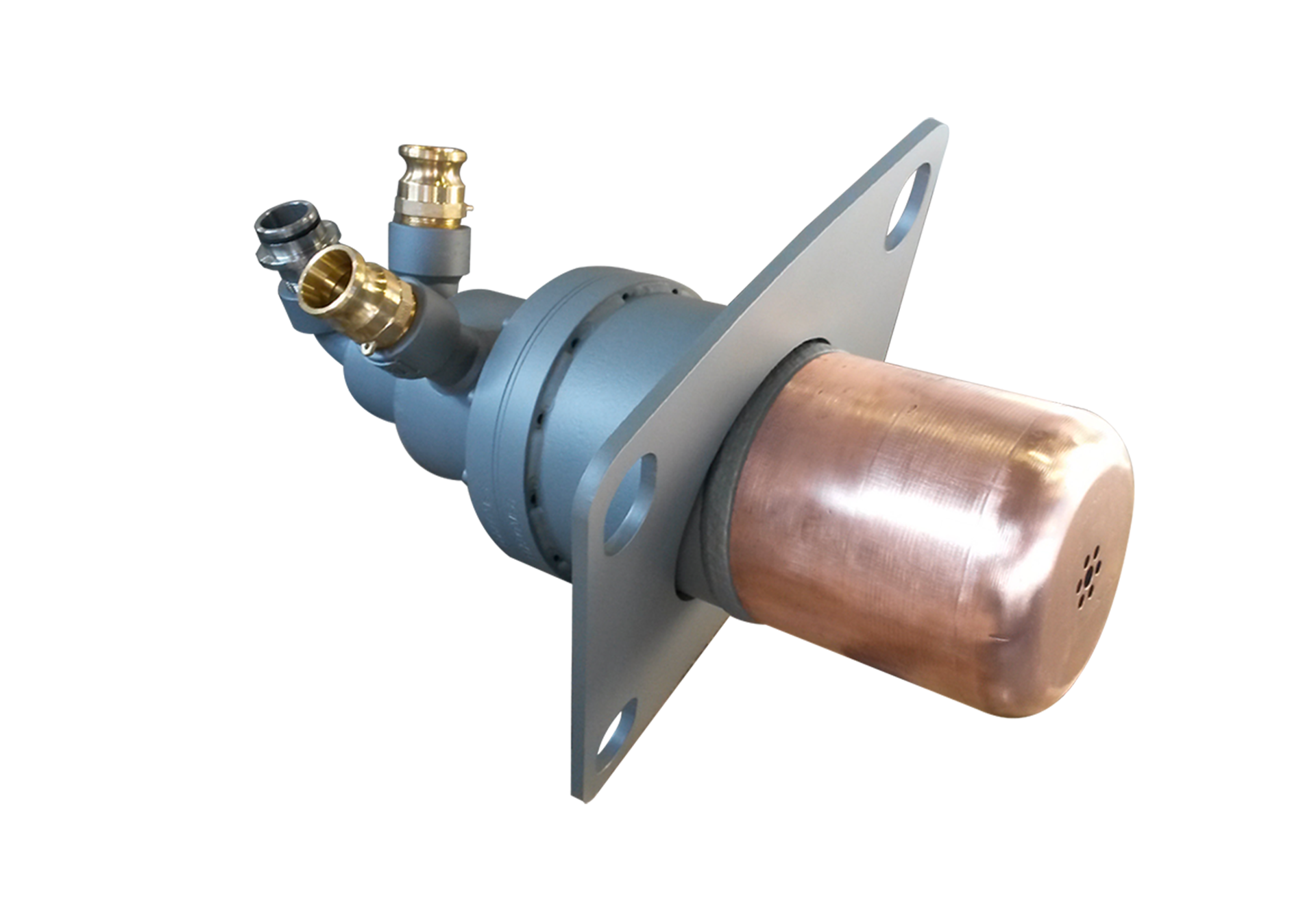

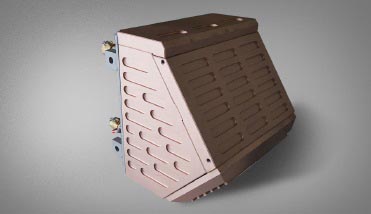

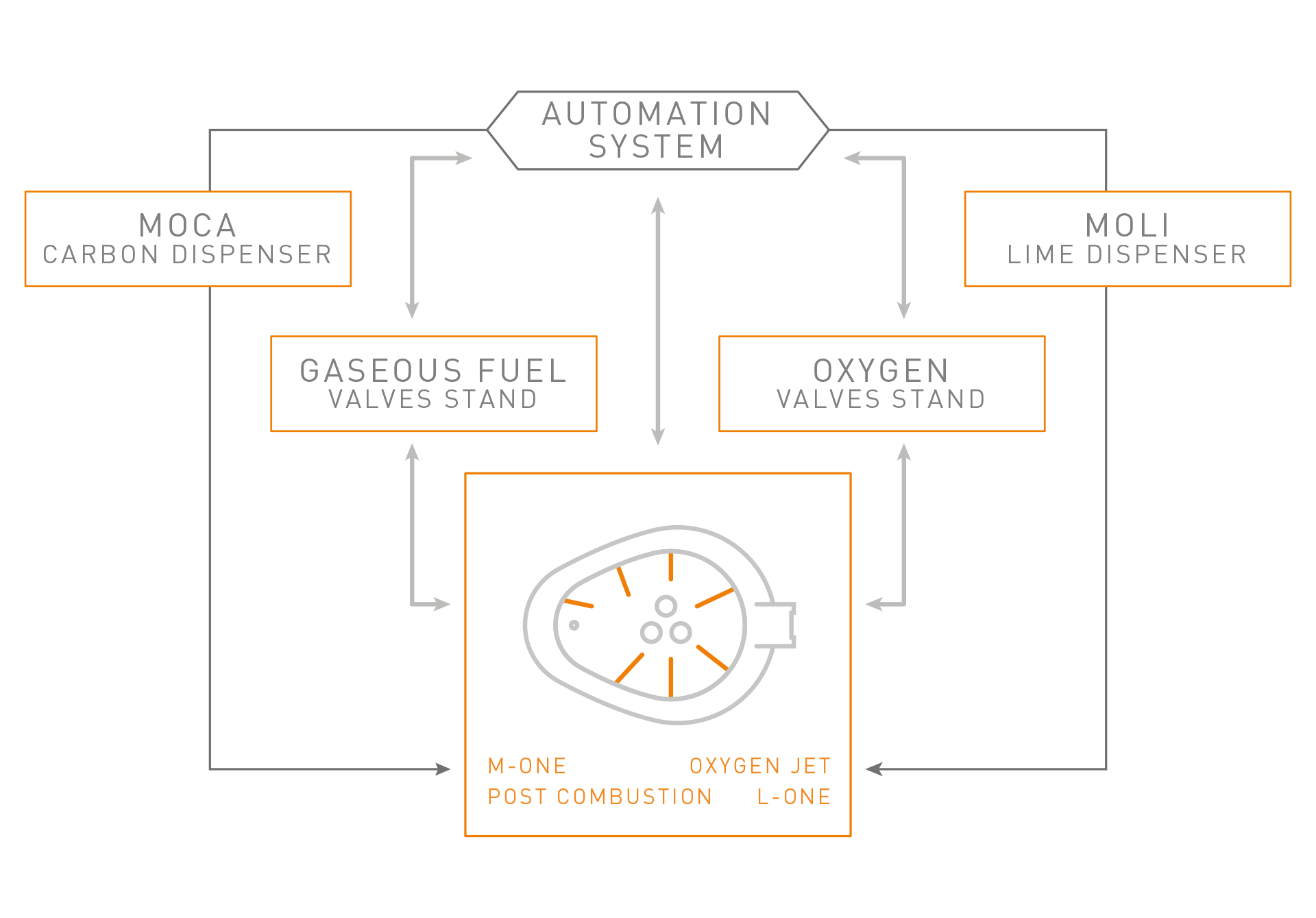

The MORE state-of-the-art chemical energy package for electric arc furnaces, combines a variety of fixed injectors and related control devices (i.e.: valve stands, carbon/fluxes dispensers, automation system and Human Machine Interface).

Injectors add chemical energy by exothermic reactions, post-combustion control and foaming slag optimization to improve the overall EAF performances and to reduce transformation costs.

BENEFITS

- Increased oxygen efficiency and carbon recovery.

- Increased metallic yield.

- Increased productivity.

- Improved foaming slag conditioning.

- Improved metallurgical process control.

- Improved overall operating efficiency.

- Improved process gas emission.

- Reduced fuel usage.

- Reduced electrical energy usage.

- Reduced power-on time.

- Reduced conversion costs.

Steelmakers can profit from the appropriate management of all these actions only if their furnace is equipped with an efficient and reliable chemical package. The most important figures required to such equipment are:

- Specialized mechanical design completed by a dedicated assembly on the furnace layout.

- Fast and precise regulation according to the melting program and the process control.

- Flexibility, reliability and consistency.

- Equipment stiffness and maintanability.

Chemical Energy Package PRODUCTS